- Home

- Vented Screw Barrel

Vented Screw Barrel

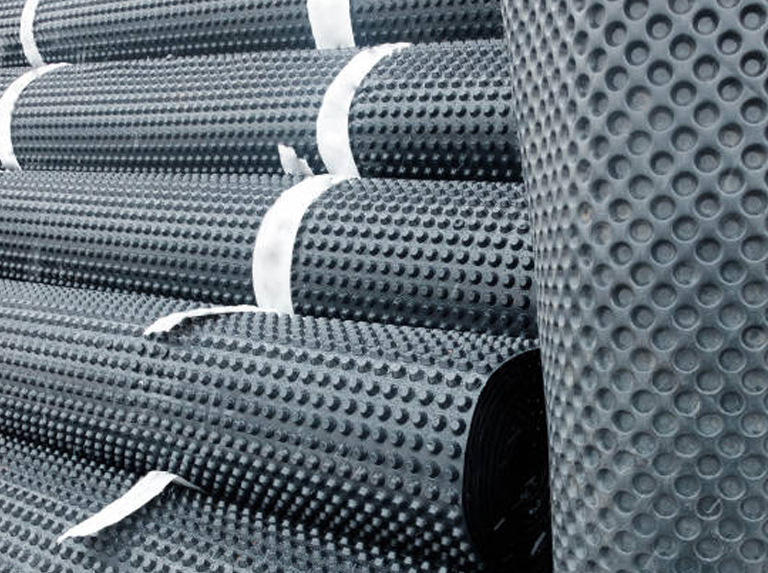

A Vented screw barrel is a specialized component used in extrusion and injection molding processes. It features a venting section designed to remove gases and volatiles from the material during processing. This venting process is crucial for achieving high-quality, defect-free products by preventing issues like bubbles, voids, and moisture-related defects.

Vented Screw Barrel

Types of Vented Screw Barrel

Benefits

Effective Gas and Volatile Removal

The venting section in our screw barrels ensures efficient removal of gases and volatiles, preventing defects and improving product quality.

Enhanced Processing Efficiency

By removing unwanted gases and volatiles, our vented screw barrels reduce the risk of defects and improve the overall efficiency of your processing operations.

Durability and Longevity

Crafted from high-grade materials, our vented screw barrels are built to withstand demanding processing conditions, offering exceptional durability and long service life.

Customization Options

We offer extensive customization options to ensure that our vented screw barrels meet your specific processing requirements. Our experienced engineers work with you to design and manufacture products that perfectly fit your application.

FAQs

What is a vented screw barrel?

A vented screw barrel is a specialized screw and barrel system designed with a venting section to remove moisture, trapped air, and volatile gases during the extrusion process. The barrel has an open vent zone, which allows unwanted gases to escape, ensuring a pure and defect-free plastic melt. It is particularly useful for processing recycled plastics, moisture-sensitive polymers, and volatile materials.

Why is venting necessary in extrusion?

Venting plays a critical role in improving the quality of extruded products by:

Eliminating trapped air and gases – Prevents defects like bubbles, voids, and inconsistent density.

Reducing moisture content – Essential for materials like PET, nylon, and recycled plastics, which absorb water.

Enhancing product finish – Ensures a smooth surface texture and structural integrity of the final product.

Increasing processing efficiency – Reduces scrap rates and improves material flow.

Without proper venting, plastics can form imperfections, weak spots, and discoloration, affecting product quality and durability.

What industries use vented screw barrels?

Vented screw barrels are widely used in industries where moisture and gas removal are crucial. These include:

Film Extrusion Industry – Used in packaging films, stretch films, and laminates to ensure transparency and strength.

Plastic Recycling Industry – Removes contaminants from recycled polymers for higher-quality reprocessed materials.

Compounding Industry – Helps in mixing additives, fillers, and stabilizers while eliminating excess gas.

Pipe & Profile Extrusion – Prevents surface defects in PVC pipes, window profiles, and industrial tubing.

Automotive & Electrical Components – Ensures defect-free parts by removing volatile residues during processing.

How does a vented screw barrel improve product quality?

A vented screw barrel ensures high-quality output by:

Removing unwanted gases and moisture, preventing bubbles or voids in the material.

Improving melt homogeneity, ensuring consistent texture and strength.

Reducing contamination, which is essential for medical-grade and food-grade plastics.

Enhancing gloss and surface finish, providing a professional, polished look.

Preventing burning and degradation, extending the lifespan of processed materials.

Can a vented screw barrel work with all types of polymers?

While vented screw barrels can be used with many polymers, they are most effective for materials that absorb moisture or release gases during processing. These include:

PET (Polyethylene Terephthalate) – Used in bottles and packaging films.

Nylon (PA6, PA66) – Used in automotive and industrial components.

ABS (Acrylonitrile Butadiene Styrene) – Ensures better mechanical properties.

PC (Polycarbonate) – Improves optical clarity and impact resistance.

Recycled Plastics – Removes impurities and residual moisture.

For non-hygroscopic materials like polyethylene (PE) and polypropylene (PP), venting is less necessary unless dealing with recycled content.

Does a vented screw barrel improve output speed?

Yes, using a vented screw barrel increases production efficiency by:

Reducing material defects, minimizing rework and scrap.

Enhancing material flow, ensuring faster melting and mixing.

Preventing overheating and thermal degradation, reducing downtime.

Allowing higher throughput, making extrusion faster and more cost-effective.

By ensuring consistent polymer processing, manufacturers can increase productivity and reduce energy consumption.

How long does a vented screw barrel last?

The lifespan of a vented screw barrel depends on factors like material type, operational load, and maintenance. On average:

Standard nitrided steel barrels last 5-7 years with moderate use.

Bimetallic and carbide-coated barrels can last 8-10 years under heavy-duty conditions.

High-wear applications (abrasive materials) may require replacement sooner.

Regular cleaning, lubrication, and wear inspections help extend service life and maintain consistent performance.

Can I retrofit my extruder with a vented screw barrel?

Yes, a vented screw barrel can be retrofitted to an existing extruder, provided the machine supports venting systems. Considerations for retrofitting include:

Machine compatibility – Ensuring the extruder has a venting port.

Screw design adaptation – Matching the screw length and compression ratio.

Proper vacuum system – Some applications require a vacuum pump for enhanced gas removal.

If you need help determining whether your extruder is compatible, we offer custom retrofitting solutions based on your machine specifications.

What coatings are available for vented screw barrels?

To improve durability and resistance to wear, corrosion, and heat, we offer several coating options:

Nitrided Steel (38CrMoAlA) – Offers good wear resistance and affordability.

Bimetallic Coating – Provides enhanced durability for abrasive and corrosive materials.

Tungsten Carbide Coating – High-strength coating for high-wear applications.

Chrome Plating – Increases corrosion resistance, ideal for processing PVC and halogen-based polymers.

Nickel-Based Coatings – Prevents oxidation and extends lifespan in high-temperature environments.

Selecting the right coating depends on the type of plastic, processing conditions, and expected wear levels.

Do you provide custom vented screw barrels?

Yes, we specialize in manufacturing custom vented screw barrels to meet specific customer needs. Our customization options include:

Barrel dimensions (diameter, length, L/D ratio) tailored to your extruder.

Different venting designs for optimal gas removal.

Material and coating options for extended durability.

Specialized heating and cooling systems for precise temperature control.

Whether you need a replacement barrel or a custom-designed solution, we can engineer and manufacture high-performance vented screw barrels to optimize your production process.

Expertise and Experience

With over 22 years of industry experience, we are leaders in the manufacturing of single screws, backed by a team of skilled professionals.

Advanced Manufacturing Facilities

Our state-of-the-art production facility is equipped with cutting-edge technology and CNC machines, ensuring precision and consistency in every component we manufacture.

Commitment to Quality

We adhere to stringent quality control standards throughout the manufacturing process, ensuring that each single screw meets our high-quality standards and exceeds customer expectations.

Customer-Centric Approach

We prioritize customer satisfaction and strive to provide personalized solutions and exceptional service. Our dedicated team is ready to assist you with technical expertise and support.