- Home

- Injection Molding Machine Screw Barrel

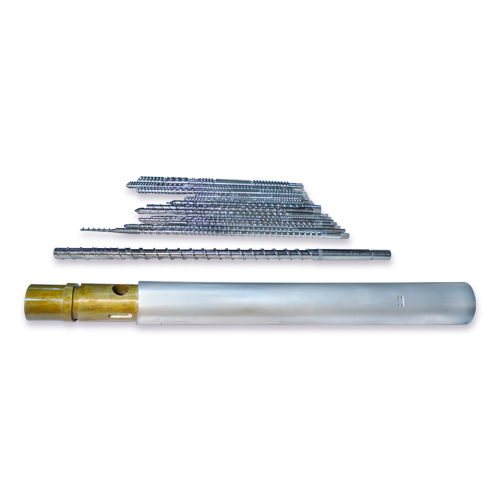

Injection Molding Machine Screw Barrel

Injection molding machine screw barrels are critical components in the injection molding process, responsible for melting, mixing, and injecting thermoplastic materials into molds to create finished plastic parts. These screw barrels are designed with precision flight geometries and materials that withstand high temperatures, pressures, and abrasive materials commonly used in injection molding.

Injection Molding Machine Screw Barrel

Download Brochure

Benefits

Precision Melt Control and Mixing

Injection molding machine screw barrels ensure precise melt control and thorough mixing of additives, colorants, and fillers into the polymer melt. This results in uniform melt quality and enhanced part aesthetics.

Extended Service Life and Durability

Our screw barrels are manufactured from high-quality materials, including nitrided steel, bimetallic alloys, and tungsten carbide coatings, to withstand abrasive wear and corrosion. This ensures extended service life and reduced maintenance downtime.

Optimized Injection Molding Parameters

By optimizing screw design and material selection, our screw barrels enhance injection molding parameters such as cycle time, shot size consistency, and part dimensional stability. This improves overall production efficiency and reduces scrap rates.

Customization Options

We offer customization options to meet specific customer requirements, including screw diameter, length-to-diameter ratio (L/D), flight geometry, material composition, and surface treatments. Our engineering expertise ensures that each injection molding machine screw barrel is optimized for maximum performance and reliability.

FAQs

What is the function of a screw barrel in an injection molding machine?

The screw barrel is a crucial component responsible for plasticizing, mixing, and injecting molten plastic into the mold cavity. The screw rotates inside the barrel, conveying plastic material while applying heat and pressure to ensure uniform melting and consistency in the final molded product.

What materials are used to manufacture injection molding machine screw barrels?

Screw barrels are typically made from high-quality nitrided steel, bimetallic alloys, or hardened tool steel. These materials enhance wear resistance, prevent corrosion, and improve longevity, especially when processing abrasive or high-temperature plastics.

How does a bimetallic screw barrel improve the performance of an injection molding machine?

Bimetallic screw barrels have a specially coated inner surface that provides superior resistance to wear, corrosion, and high temperatures. This extends the lifespan of the screw barrel and ensures consistent plastic processing, reducing maintenance downtime and improving overall productivity.

What factors determine the design of an injection molding screw barrel?

The design of a screw barrel depends on various factors, including the type of plastic material used, required melt temperature, injection pressure, barrel length-to-diameter (L/D) ratio, and the type of molding application. Custom designs optimize material flow and improve efficiency.

How can I increase the lifespan of my injection molding screw barrel?

Regular maintenance, proper temperature control, and using high-quality raw materials can significantly extend the lifespan of the screw barrel. Avoiding excessive wear by using the right screw design for specific materials also helps in preventing premature damage.

What are the signs that indicate a screw barrel needs replacement?

Common signs of wear include inconsistent melt flow, increased cycle times, poor plastic mixing, visible wear on the screw flights, and frequent defects in molded parts. If these issues arise, inspecting and potentially replacing the screw barrel is recommended.

Can a single screw barrel be used for multiple plastic materials?

While some general-purpose screw barrels can handle different plastic types, specialized screws are designed for better performance with specific materials. For example, barrier screws are ideal for processing high-viscosity polymers, while vented screws help with moisture-sensitive plastics.

What is the typical lead time for manufacturing a custom screw barrel?

The production time for a custom screw barrel varies based on size, design complexity, and material selection. On average, it can take anywhere from 2 to 6 weeks to manufacture a high-precision screw barrel tailored to a specific injection molding machine.

How does the screw design impact the efficiency of an injection molding machine?

The screw design plays a critical role in material melting, flow rate, and cycle time. Factors like screw diameter, compression ratio, and mixing sections influence energy efficiency, material homogenization, and the overall quality of molded products.

Do you provide installation support and maintenance services for screw barrels?

Yes, we offer complete installation guidance, technical support, and maintenance services for screw barrels. Our team can assist in proper alignment, troubleshooting, and reconditioning to maximize machine performance and extend the lifespan of the screw barrel.

Why Choose Us?

Expertise and Experience

With over 22 years of industry experience, we are leaders in the manufacturing of single screws, backed by a team of skilled professionals.

Advanced Manufacturing Facilities

Our state-of-the-art production facility is equipped with cutting-edge technology and CNC machines, ensuring precision and consistency in every component we manufacture.

Commitment to Quality

We adhere to stringent quality control standards throughout the manufacturing process, ensuring that each single screw meets our high-quality standards and exceeds customer expectations.

Customer-Centric Approach

We prioritize customer satisfaction and strive to provide personalized solutions and exceptional service. Our dedicated team is ready to assist you with technical expertise and support.