- Home

- Groove Feed Screw Barrel

Groove Feed Screw Barrel

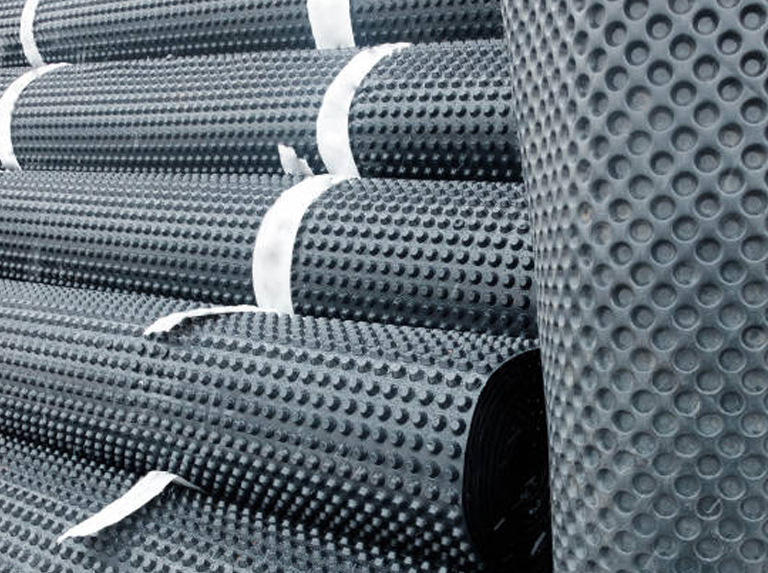

The use of groove feed in an extruder for higher output & better process stability. It includes the benefits like increased output, reduced melt temperature, improved mixing quality and liner consistency. Due to the nature of groove feed design, frictional forces are higher, thus moving solids forward faster than a smooth bore extruder. This also enables higher processing rates with a lower melt temperature.

Groove Feed Screw Barrel

Types of Groove Feed Screw Barrel

Benefits

Enhanced Material Intake

The grooved design in the feed section significantly improves material intake, ensuring a consistent and steady feed into the processing section.

Reduced Bridging and Surging

Our groove feed screw barrels minimize the risk of bridging and surging, providing smoother and more reliable operation.

Improved Conveying Efficiency

The optimized design enhances the conveying efficiency, leading to increased throughput and improved overall productivity.

Durability and Longevity

Crafted from high-grade materials, our groove feed screw barrels are built to withstand demanding processing conditions, offering exceptional durability and long service life.

FAQs

What is a groove feed screw barrel?

A groove feed screw barrel is a specialized screw barrel with grooved feeding sections in the hopper area. These grooves enhance material intake, improve conveying stability, and optimize plasticizing efficiency.

Key Feature: Grooves in the feed section increase material friction and prevent slippage.

Result: Higher throughput, better melt homogeneity, and improved processing efficiency.

Why use a groove feed screw barrel?

A groove feed screw barrel offers several advantages over conventional smooth-bore screw barrels:

Enhanced Material Intake – The grooves prevent slippage, improving feeding efficiency.

Improved Plasticizing Capacity – Ensures better melting and homogenization.

Reduced Feed Fluctuations – Provides a stable and consistent material flow.

Higher Output & Throughput – Ideal for high-performance extrusion processes.

Better Pressure Build-Up – Improves melt uniformity and reduces processing variations.

This specialized barrel design is ideal for high-output and high-precision extrusion applications.

Which industries use groove feed screw barrels?

Groove feed screw barrels are commonly used in extrusion applications that require high efficiency and stable material flow, such as:

Pipe Extrusion: Used for PVC, PE, and PPR pipes.

Film Extrusion: Ideal for plastic film manufacturing (e.g., blown and cast film).

Compounding & Masterbatch Processing: Ensures uniform mixing of additives and fillers.

Profile & Sheet Extrusion: Used in window profiles, plastic sheets, and construction materials.

Cable & Wire Coating: Enhances precision in polymer coating applications.

These industries benefit from the higher processing stability and increased material throughput of groove feed screw barrels.

What materials are groove feed screw barrels made from?

Groove feed screw barrels are built from high-durability materials to withstand abrasive and high-temperature processing conditions.

Base Material:

Hardened Alloy Steel (38CrMoAlA, 42CrMo) – Provides high strength and wear resistance.

Coating & Surface Treatment:

Nitrided Coating (Plasma or Gas Nitriding) – Increases hardness and wear resistance.

Bimetallic Coating (Nickel-Based, Tungsten Carbide, or Cobalt Alloy) – Enhances resistance to corrosion, abrasion, and high-temperature degradation.

The material selection depends on the type of plastic being processed and the required wear resistance.

How does a groove feed screw barrel improve extrusion?

A groove feed screw barrel improves the extrusion process by:

Increasing Material Friction in the Feed Zone – Reduces slippage and enhances feeding efficiency.

Ensuring Consistent Material Flow – Prevents fluctuations, improving product uniformity.

Enhancing Melt Homogeneity – Reduces defects and ensures even material distribution.

Improving Energy Efficiency – Less energy is required to maintain consistent material pressure.

This results in higher quality output, lower defect rates, and better overall process stability.

Can I retrofit my machine with a groove feed screw barrel?

Yes, but compatibility must be checked before retrofitting. Factors to consider include:

Machine Type & Configuration: Groove feed barrels are ideal for extruders designed to handle increased material intake.

Feeding System Compatibility: The feed throat and hopper design must align with the grooved barrel structure.

Processing Material Requirements: Some materials benefit more from a grooved feed system than others.

If compatible, a retrofit can significantly enhance extrusion performance.

How long does a groove feed screw barrel last?

The lifespan of a groove feed screw barrel depends on factors like:

Material Processed: Abrasive and high-filler materials shorten lifespan.

Operating Conditions: Higher temperatures and speeds increase wear.

Maintenance Practices: Proper cleaning and lubrication extend longevity.

Typical Lifespan: 8-12 years with regular maintenance.

Compared to Standard Barrels: 30-50% longer service life due to better wear resistance.

Regular monitoring of wear patterns can help determine the right time for replacement or refurbishment.

Does a groove feed screw barrel require special maintenance?

Yes, some specific maintenance steps are required to keep the groove feed barrel in optimal condition:

Regular Cleaning of Grooves: Prevents material buildup and blockages.

Wear Monitoring: Inspect for signs of excessive wear or damage.

Proper Lubrication: Ensures smooth screw rotation and minimizes friction.

Temperature Control Management: Prevents overheating that could degrade material properties.

Following these maintenance steps ensures longer service life and consistent performance.

Can it handle high-speed extrusion?

Yes, groove feed screw barrels are specifically designed for high-speed and high-output extrusion applications.

Optimized Material Intake – Prevents feeding inconsistencies at high speeds.

Better Pressure Build-Up – Ensures uniform melt flow and stable processing.

Reduced Backflow & Slippage – Enhances extrusion efficiency and product quality.

This makes it ideal for demanding production environments requiring fast and efficient material processing.

Do you provide custom groove feed screw barrels?

Yes! We manufacture custom groove feed screw barrels tailored to your specific extrusion requirements, including:

Material Customization: Nitrided or bimetallic coatings for extended durability.

Groove Design Optimization: Adjusted groove depth and spacing for maximum efficiency.

Barrel Length & Diameter: Custom dimensions to fit different extruder models.

Specialized Screw Designs: Optimized for various plastic formulations.

Our custom manufacturing process ensures precision, efficiency, and long-term performance.

Expertise and Experience

With over 22 years of industry experience, we are leaders in the manufacturing of single screws, backed by a team of skilled professionals.

Advanced Manufacturing Facilities

Our state-of-the-art production facility is equipped with cutting-edge technology and CNC machines, ensuring precision and consistency in every component we manufacture.

Commitment to Quality

We adhere to stringent quality control standards throughout the manufacturing process, ensuring that each single screw meets our high-quality standards and exceeds customer expectations.

Customer-Centric Approach

We prioritize customer satisfaction and strive to provide personalized solutions and exceptional service. Our dedicated team is ready to assist you with technical expertise and support.