- Home

- Barrier Screw Barrel

- Barrier Screw

Barrier Screw

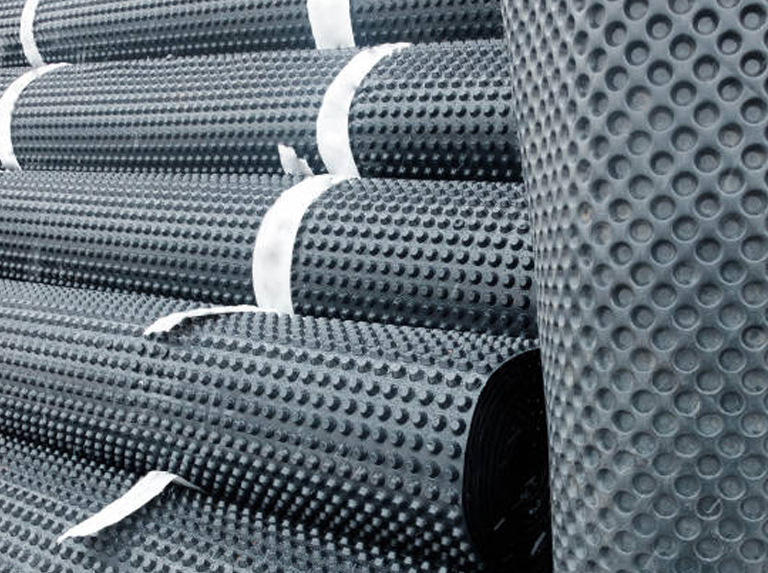

Barrier screws are specialized extrusion screws designed to enhance mixing, melting, and conveying of plastics during the extrusion process. They feature a unique design with a barrier flight that creates a barrier between the solids conveyed in the screw and the melt pool. This design helps to improve melt homogeneity, increase throughput, and reduce melt temperature variations, resulting in higher-quality extruded products.

Barrier Screw

Benefits

Enhanced Mixing and Melting Efficiency

Barrier screws facilitate thorough mixing of additives and colorants into the polymer melt, ensuring uniform distribution and improved material properties. This results in consistent product quality and reduced scrap rates.

Improved Melt Homogeneity

The barrier flight design creates a barrier between the solid particles and the melt pool, promoting better dispersion and homogenization of materials. This helps to eliminate melt variations and achieve uniform product characteristics.

Increased Throughput and Efficiency

By optimizing melt conveying and reducing shear heating, barrier screws enhance extrusion throughput while minimizing energy consumption. This leads to higher production efficiency and lower operational costs over time.

Temperature and Pressure Control

Barrier screws enable precise control over melt temperature and pressure profiles throughout the extrusion process. This capability is crucial for achieving consistent product dimensions, surface finish, and mechanical properties.

FAQs

What is a barrier screw?

A barrier screw is an advanced extruder screw that features an additional flight (barrier section) to improve polymer melting, homogenization, and process efficiency. It helps in maintaining separation between solid and molten plastic, leading to better thermal control, reduced defects, and higher output rates.

Why is a barrier screw better than a standard screw?

A barrier screw offers several advantages over standard screws, such as:

Faster melting and better temperature control, reducing overheating.

Higher material homogeneity, preventing inconsistent product quality.

Reduced energy consumption, leading to cost savings.

Increased extrusion speed, boosting production rates.

What materials are used for barrier screws?

Barrier screws are manufactured from high-performance materials to ensure durability, wear resistance, and efficient heat transfer. Common materials include:

Nitrided Steel (38CrMoAlA) – Provides high surface hardness, excellent wear resistance, and protection against corrosion.

Tool Steel (D2, H13, etc.) – Used in high-pressure and high-temperature applications where additional strength is required.

Bimetallic Alloys (Nickel or Tungsten Carbide Coatings) – Ideal for processing abrasive or filled polymers (e.g., fiberglass-filled or calcium carbonate-filled resins).

Stainless Steel (440C, 17-4PH) – Used in applications where corrosion resistance is a priority, such as medical and food-grade plastics.

The choice of material depends on processing conditions, polymer type, and required durability.

Where are barrier screws used?

Barrier screws are widely used in plastic processing industries where enhanced melting and mixing efficiency is required. Applications include:

Extrusion Processes

Pipe & Profile Extrusion – Ensures uniform melt flow and better dimensional stability.

Sheet & Film Extrusion – Reduces gels, unmelted particles, and thermal degradation.

Compounding Extrusion – Improves filler dispersion and additive mixing.

Injection Molding

Used in automotive, medical, and packaging industries for complex mold designs.

Enhances melt uniformity, reducing defects like weld lines and voids.

Blow Molding

Produces plastic bottles, fuel tanks, and hollow containers.

Improves wall thickness uniformity and reduces cycle time.

Barrier screws are particularly beneficial when processing high-viscosity polymers, ensuring better melt homogenization and cycle efficiency.

How does a barrier screw improve polymer processing?

A barrier screw enhances polymer processing by addressing common issues in melting, mixing, and material degradation. Key benefits include:

Optimized Melt Flow – The unique barrier flight design separates the melted and unmelted plastic, ensuring controlled melting and preventing overheating.

Improved Temperature Control – Enhances heat transfer efficiency, reducing the chances of burnt or degraded material.

Better Mixing & Homogeneity – Promotes uniform distribution of colorants, fillers, and stabilizers, improving final product consistency.

Higher Processing Efficiency – Reduces residence time and eliminates unmelted granules, increasing output rate.

Minimizes Material Waste – Reduces material degradation, improving recyclability of processed polymers.

Barrier screws are particularly beneficial for processing polyolefins (PP, PE), PVC, PET, and engineering plastics (PC, ABS, Nylon, etc.).

Can I replace my standard screw with a barrier screw?

Yes, but certain factors must be checked before replacement:

Machine Compatibility – Ensure that the barrel and drive system support barrier screw installation.

Material Type – Barrier screws are ideal for difficult-to-process materials, but adjustments may be needed for highly shear-sensitive polymers.

Processing Conditions – Consider screw length, compression ratio, and flight design to optimize performance.

Output Requirements – A barrier screw improves efficiency but may require adjustments to back pressure and temperature settings.

Before replacing a standard screw, consult a manufacturer to determine the best screw configuration for your specific application.

Does a barrier screw increase production speed?

Yes, a barrier screw significantly improves production efficiency due to:

Faster Melting Rates – The barrier flight separates the solid and melt zones, reducing the time required for complete plasticization.

Better Heat Control – Maintains a stable temperature profile, preventing overheating or underheating of polymers.

Improved Material Flow – Reduces backflow and stagnation, allowing for a more consistent output.

Minimized Downtime – Enhanced mixing reduces defects, minimizing machine stops for quality adjustments.

In some applications, a barrier screw can increase output rates by 15-30% compared to a conventional screw.

What is the lifespan of a barrier screw?

With proper maintenance, a barrier screw typically lasts between 6 to 10 years.

However, its lifespan depends on:

Material Processed – Highly abrasive polymers (e.g., glass-filled compounds) reduce lifespan.

Operating Conditions – Higher temperatures and pressure can accelerate wear.

Screw Material – Bimetallic coatings significantly extend durability.

Maintenance Practices – Regular cleaning and wear inspections prevent premature failure.

Investing in a high-quality barrier screw can significantly reduce replacement frequency and downtime costs.

Does a barrier screw require special maintenance?

Yes, regular maintenance is essential to ensure longevity and optimal performance.

Key Maintenance Practices:

Routine Cleaning – Prevents buildup of degraded plastic and residue contamination.

Lubrication – Ensures smooth operation and reduces frictional wear.

Wear Inspections – Periodically check for flight wear, pitting, or erosion to avoid performance loss.

Proper Startup & Shutdown Procedures – Avoid sudden temperature changes that cause thermal stress and cracking.

Use of Purging Compounds – Helps remove stubborn deposits and ensures a clean processing environment.

Ignoring maintenance can shorten screw lifespan and affect production quality.

Do you provide custom barrier screws?

Yes! We offer fully customized barrier screws tailored to specific extrusion and molding needs.

Customization Options:

Screw Diameter & Length – Adjusted to match machine requirements.

Flight Depth & Pitch – Optimized for specific polymer processing needs.

Barrier Flight Design – Engineered for enhanced melting and mixing performance.

Coatings & Surface Treatments – Available for abrasion and corrosion resistance.

Custom barrier screws help achieve higher output, better quality, and reduced operational costs.

Expertise and Experience

With over 22 years of industry experience, we are leaders in the manufacturing of single screws, backed by a team of skilled professionals.

Advanced Manufacturing Facilities

Our state-of-the-art production facility is equipped with cutting-edge technology and CNC machines, ensuring precision and consistency in every component we manufacture.

Commitment to Quality

We adhere to stringent quality control standards throughout the manufacturing process, ensuring that each single screw meets our high-quality standards and exceeds customer expectations.

Customer-Centric Approach

We prioritize customer satisfaction and strive to provide personalized solutions and exceptional service. Our dedicated team is ready to assist you with technical expertise and support.