- Home

- Screw Barrel

- Single Barrel

Single Barrel

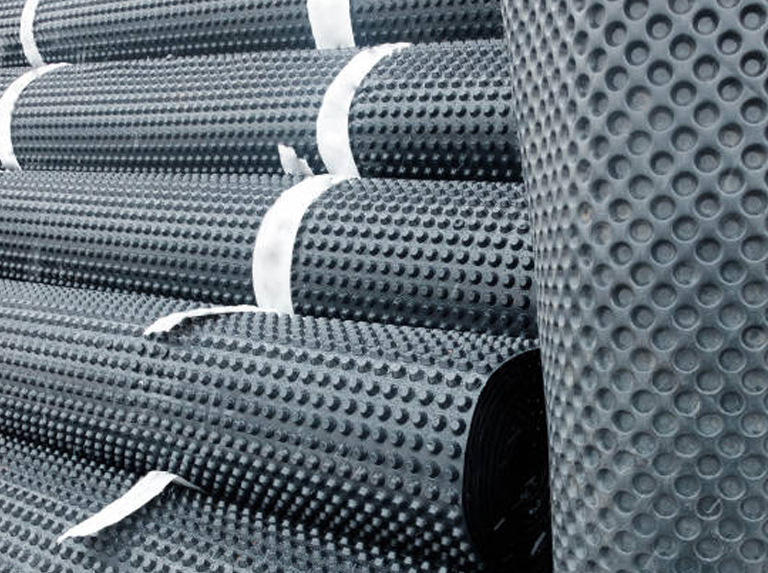

A single barrel refers to a cylindrical component used in extrusion and injection molding machinery. It serves as the housing for screws, providing a controlled environment where raw materials are heated, mixed, and shaped into finished products. Single barrels are crucial for maintaining consistent processing conditions and ensuring high-quality output across various industrial applications.

Single Barrel

Benefits

Enhanced Processing Efficiency

Single barrels play a critical role in optimizing material heating, mixing, and shaping processes, contributing to increased throughput, reduced cycle times, and improved overall production efficiency.

Consistent Product Quality

By providing a stable processing environment, our single barrels help ensure uniform product characteristics, minimizing defects and enhancing customer satisfaction.

Durable and Reliable Performance

Crafted from premium materials, our single barrels are built to withstand the rigors of continuous operation, ensuring long-term performance and minimal maintenance.

Customization Options

We offer extensive customization options to meet specific customer requirements. Whether optimizing for thermal stability, wear resistance, or specific processing needs, our flexible manufacturing capabilities enable us to deliver barrels that align perfectly with your operational goals.

FAQs

What is the function of a single barrel?

A single barrel is a cylindrical housing that holds the rotating screw in extrusion or injection molding machines. It plays a crucial role in heating, melting, and conveying plastic material, ensuring uniform processing.

What materials are used to manufacture single barrels?

Single barrels are typically made from:

Nitrided steel (38CrMoAlA): Offers good hardness and resistance to wear.

Hardened tool steel: Provides extra strength for high-temperature applications.

Bimetallic alloys: Ideal for abrasive and corrosive materials, offering longer service life.

How does a worn-out barrel affect production?

A damaged or worn barrel causes:

Uneven material flow, leading to defects in the final product.

Reduced heating efficiency, increasing energy consumption.

Leakage and pressure loss, decreasing overall machine performance.

Can a single barrel be reconditioned instead of replaced?

Yes, if wear is not severe, the barrel can be re-bored, re-nitrided, or relined to restore performance. However, deep cracks, excessive wear, or deformations may require full replacement.

What are the advantages of using a bimetallic single barrel?

Higher wear resistance for processing abrasive materials.

Better corrosion protection against aggressive chemicals.

Extended lifespan, reducing replacement costs and downtime.

How do I know when to replace my single barrel?

Signs that indicate a need for replacement include:

Poor material flow or uneven melting.

Increased cycle times and higher energy consumption.

Leakage or excessive screw wear due to misalignment.

Can I get a custom-sized single barrel?

Yes, we manufacture custom single barrels tailored to machine specifications, including length, diameter, and special coatings for specific processing needs.

How long does it take to manufacture a single barrel?

Standard barrels: Available within a week.

Custom orders: Typically 2-4 weeks based on complexity.

What industries use single barrels?

Single barrels are widely used in:

Plastic extrusion and injection molding

Rubber processing

Food and pharmaceutical industries (with special coatings)

What maintenance tips help prolong the life of a single barrel?

Use high-quality raw materials to prevent excessive wear.

Regularly clean and inspect the barrel for buildup or damage.

Maintain optimal temperature settings to avoid overheating.

Expertise and Experience

With over 22 years of industry experience, we are leaders in the manufacturing of single screws, backed by a team of skilled professionals.

Advanced Manufacturing Facilities

Our state-of-the-art production facility is equipped with cutting-edge technology and CNC machines, ensuring precision and consistency in every component we manufacture.

Commitment to Quality

We adhere to stringent quality control standards throughout the manufacturing process, ensuring that each single screw meets our high-quality standards and exceeds customer expectations.

Customer-Centric Approach

We prioritize customer satisfaction and strive to provide personalized solutions and exceptional service. Our dedicated team is ready to assist you with technical expertise and support.