Screw Barrel

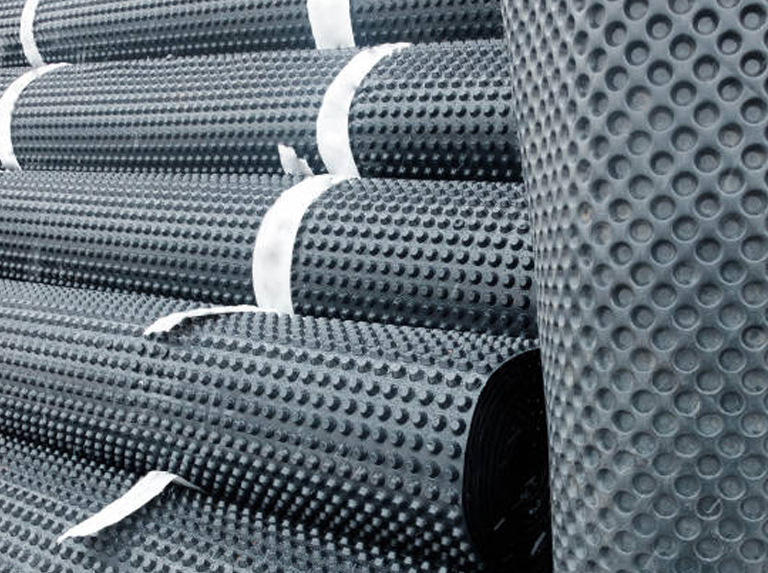

A screw barrel is a critical component in machinery used for the extrusion, injection molding, and processing of materials such as plastics, rubber, and metals. It consists of a helical screw rotating inside a cylindrical barrel, where raw materials are melted, mixed, and conveyed to form finished products. The efficiency and performance of the screw barrel directly impact the quality and productivity of the manufacturing process.

Screw Barrel

Types of Screw Barrels

Benefits

High-Quality Materials

We use only the finest materials in our screw barrels, ensuring they deliver exceptional performance and longevity even in the most demanding environments.

Precision Manufacturing

Our state-of-the-art manufacturing facility is equipped with advanced CNC machines and technology, allowing us to produce screw barrels with unmatched precision and consistency.

Rigorous Quality Control

Every screw barrel undergoes stringent quality control checks to ensure it meets our high standards. From material selection to final inspection, we guarantee top-notch quality in every product.

Competitive Pricing

Despite our commitment to quality, we offer competitive pricing to ensure you get the best value for your investment. Our efficient production processes and economies of scale allow us to provide cost-effective solutions without compromising on quality.

FAQs

What materials are used in manufacturing screw barrels?

Screw barrels are typically made from high-quality materials such as nitrided steel (38CrMoAlA), bimetallic alloys, or hardened tool steel to provide excellent wear resistance, corrosion protection, and durability. Nitrided steel offers high hardness and longevity, while bimetallic screw barrels have a special alloy coating to withstand abrasion and chemical wear, making them ideal for high-performance applications. Hardened tool steel is used for extreme conditions where maximum toughness is required.

How do I choose the right screw barrel for my machine?

Selecting the correct screw barrel depends on several factors, including:

Machine type: Different machines require specific barrel designs.

Processing material: The type of plastic, rubber, or other material you are processing determines the required barrel material.

Output capacity: The barrel should match the desired production rate.

Wear resistance needs: If you process abrasive or corrosive materials, a bimetallic barrel is recommended for longer life.

Barrel dimensions: Ensuring compatibility with your machine’s screw diameter and length is crucial.

Consulting with our experts can help you determine the most suitable screw barrel for your needs.

What is the lifespan of a screw barrel?

The lifespan of a screw barrel depends on factors such as material quality, maintenance, and operating conditions. Generally, a well-maintained screw barrel lasts between 3 to 10 years. Nitrided steel barrels may require re-nitriding after extended use, while bimetallic barrels offer longer durability due to their wear-resistant coating. Regular cleaning, proper lubrication, and avoiding high-friction materials help extend the barrel’s life.

Can a damaged screw barrel be repaired?

Yes, minor damage such as surface wear, scratches, and small deformations can be repaired through resurfacing, re-nitriding, or honing. However, if the inner bore is excessively worn or cracked, replacement is often the best option. Bimetallic barrels may also be refurbished by applying a new wear-resistant coating. Our team can assess the damage and recommend the most cost-effective solution.

What are the advantages of using a bimetallic screw barrel?

Bimetallic screw barrels are designed for superior performance in demanding applications. Key benefits include:

Enhanced wear resistance: Ideal for abrasive materials like glass-filled plastics, PVC, and fiber-reinforced compounds.

Corrosion protection: Resistant to chemical degradation from acidic or alkaline materials.

Longer service life: Lasts significantly longer than nitrided steel barrels, reducing maintenance and downtime.

Improved thermal stability: Ensures consistent processing with better heat retention and distribution.

Cost-effective in the long run: Though initially more expensive, its durability reduces replacement costs.

Do you provide customized screw barrels?

Yes, we specialize in custom screw barrels tailored to your machine’s specifications. Our team designs barrels based on:

Screw diameter and length

L/D ratio (Length-to-Diameter ratio)

Processing material requirements

Wear and corrosion resistance needs

Cooling and heating elements compatibility

How long does it take to deliver a screw barrel?

Delivery time varies based on the type and customization required:

Standard-sized screw barrels are usually available for immediate shipping.

Customized screw barrels take approximately 2 to 4 weeks, depending on complexity and material availability.

Urgent orders may be expedited with an additional fee.

We ensure timely delivery with robust packaging to prevent damage during transit.

Do you provide installation assistance?

Yes, we offer installation guidance and technical support to ensure a proper fit and seamless operation. Our services include:

Step-by-step installation instructions

On-site assistance (for bulk or industrial orders)

Video demonstrations and remote support

Calibration and alignment tips for optimal performance

Proper installation is crucial to prevent issues such as misalignment, uneven wear, or reduced efficiency.

What industries commonly use your screw barrels?

Our screw barrels are widely used in various industries, including:

Plastic extrusion: PVC pipes, profiles, sheets, films, and cables manufacturing.

Injection molding: Automotive components, consumer goods, and medical devices production.

Rubber processing: Tire manufacturing, rubber sheets, and industrial rubber products.

Recycling industry: Processing of reclaimed plastic and rubber into reusable materials.

Food and pharmaceutical industries: Special screw barrels for food-grade and medical applications.

Our barrels are designed to handle a wide range of materials, ensuring efficiency and longevity in different industrial applications.

How do I maintain my screw barrel for optimal performance?

Regular maintenance is essential to extend the lifespan and efficiency of your screw barrel. Key maintenance tips include:

Regular cleaning: Remove residual materials using proper cleaning agents to prevent buildup and contamination.

Proper lubrication: Use recommended lubricants to reduce friction and wear.

Avoid abrasive materials: If processing highly abrasive compounds, use bimetallic barrels for better durability.

Monitor temperature settings: Excessive heat can cause premature wear or deformation. Ensure proper heating and cooling control.

Routine inspections: Check for signs of wear, cracks, or deformation. Early detection prevents costly breakdowns.

Correct alignment: Ensure the screw and barrel are properly aligned to avoid uneven wear and tear.

Following these maintenance practices helps in achieving consistent production quality and extending the life of your screw barrel.

Expertise and Experience

With over 22 years of industry experience, we are leaders in the manufacturing of single screws, backed by a team of skilled professionals.

Advanced Manufacturing Facilities

Our state-of-the-art production facility is equipped with cutting-edge technology and CNC machines, ensuring precision and consistency in every component we manufacture.

Commitment to Quality

We adhere to stringent quality control standards throughout the manufacturing process, ensuring that each single screw meets our high-quality standards and exceeds customer expectations.

Customer-Centric Approach

We prioritize customer satisfaction and strive to provide personalized solutions and exceptional service. Our dedicated team is ready to assist you with technical expertise and support.